IPI Box Guide

The IPI Group, LLC

CORRUGATED BOX GUIDE

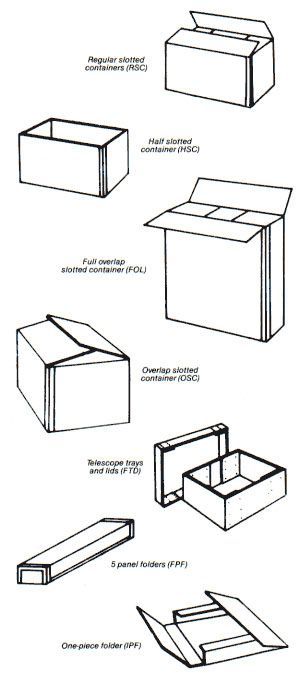

Corrugated Box Styles

IPI Group LLC manufactures primarily large or small custom boxes for oversized and difficult to pack items but also distribute a full line of stock boxes. The following is a basic list of the different box styles we manufacture. If you don't see what you need, we can also design new styles depending on your needs!

Please Note: Boxes are measured as length x width x height which means the length & width dimensions are the opening of the box with the length being the longer of the two dimensions and the width the smaller dimension. The height is the dimension down into the box from the top (please see bottom of page for more detailed info on measuring your box!)

MEASURING YOUR BOX (BOX DIMENSIONS)

Dimensions are given in the sequence of length, width, and depth. The dimensions of a box are described based on the opening of an assembled box, which can be located on the top or the side, depending on how it is to be filled. The opening of a box is rectangular (it has two sets of parallel sides). The longer of the two sides is considered its length, the shorter of the two sides is considered its widthThe side perpendicular to length and width is considered the depth of the box. When supplying measurements always use the inside dimensions of the box!

For example: A box that measures 27" x 15" x 18" would have an opening that is 27" x 15" and would measure 18" from top to bottom). The flaps would meet on the 15" width and the tape closure would run the 27" length of the box. The measurements are always ID (Inside Dimensions) unless otherwise specified.

DOUBLE WALL (DW) OR SINGLE WALL (SW)?

The two most common types of corrugated cardboard are double wall and single wall

Singlewall (SW) - The most common type of corrugation material used in boxes. It consists of one medium (flute) glued between two sheets of linerboard. It is available in a wide range of strengths. For most customers, singlewall boxes provide the protection and durability required at an affordable price.

Doublewall (DW) - Much more resistant to punctures or crushing when stacked. It consists of two mediums (flutes) glued between three sheets of linerboard. Just like singlewall, it is also available in a variety of strengths. Doublewall allows for heavier objects to be shipped and stacked and should be used when a stronger box or extra padding is needed.

Edge Crush Test (ECT) vs. Bursting Strength

There are currently two tests used throughout the corrugated industry to determine strength.

The newest and most common standard used is the Edge Crush Test (ECT). This test directly relates to the stacking strength of a box. ECT measures the edgewise compressive strength of corrugated board. It is measured by compressing a small piece of board on edge between two plates perpendicular to the direction of the flutes until a peak load is determined. ECT is measured in pounds per lineal inch of load bearing edge (lb/in), and normally reported as an ECT value (example: 44 ECT).

Bursting Test is a measure of the force required to puncture the corrugated board and is measured by a Mullen Tester. This force is indirectly related to a box's ability to withstand external or internal forces and therefore protect a product during shipment. Bursting strength is reported in pounds (example: 275#).

Share On: